The Advantages of Using a Robotic Welding System

Introduction

Welcome to Cresco Custom Metals, your premier destination for all your metal fabrication needs. In today's fast-paced business environment, staying ahead of the competition is crucial. We understand the importance of integrating cutting-edge technologies to enhance productivity and efficiency, which is why we specialize in providing high-end robotic welding systems.

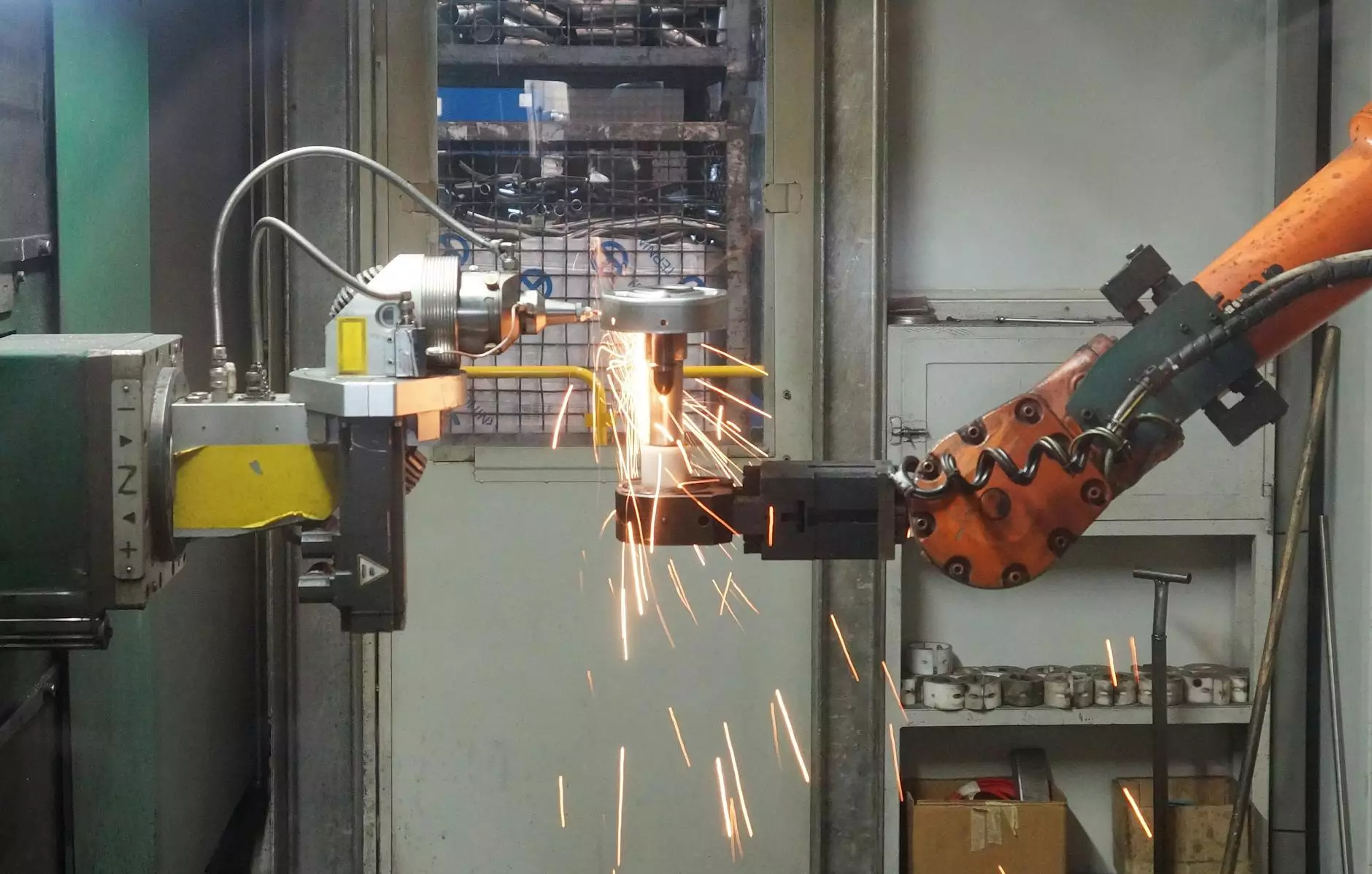

Why Choose a Robotic Welding System?

When it comes to metal fabricators, utilizing a robotic welding system offers numerous advantages. Let's explore why this advanced technology is revolutionizing the industry.

1. Increased Efficiency and Productivity

Robotic welding systems have proven to be significantly faster and more efficient than traditional welding methods. With precise motion control and high-speed welding capabilities, these systems can complete complex welding tasks in a fraction of the time it would take a human operator. This leads to increased productivity and shorter turnaround times, allowing your business to take on more projects and maximize profitability.

2. Consistency and Quality

One of the biggest challenges in welding is maintaining consistent quality across every joint. Human welders can be susceptible to inconsistencies due to fatigue, angle discrepancies, or varying skill levels. In contrast, robotic welding systems deliver unrivaled precision, ensuring that each weld is executed with the utmost accuracy and repeatability. This consistency guarantees superior quality with minimal defects, ultimately elevating the standards of your metal fabrication projects.

3. Enhanced Safety

Welding often involves hazardous working conditions, with exposure to high temperatures, sparks, and fumes. By deploying robotic welding systems, you can significantly reduce the risks associated with human welders' exposure to these safety hazards. Advanced sensors and safety protocols ensure that the operations are conducted in a controlled environment, minimizing the chances of accidents or injury. This prioritizes the well-being of your workforce and creates a safer workplace overall.

4. Cost Reduction

Although investing in a robotic welding system may seem like a significant initial expense, it quickly pays off in the long run. These systems provide cost savings by optimizing material usage, reducing rework, and minimizing weld failure rates. Additionally, the faster cycle times and increased productivity lead to higher throughput, enabling your business to handle larger workloads without additional labor costs. When carefully integrated into your metal fabrication processes, these systems become a cost-effective solution that boosts your bottom line.

5. Versatility and Adaptability

Robotic welding systems offer immense flexibility in handling various welding applications. Whether you work with stainless steel, aluminum, or complex assemblies, these systems are designed to adapt to different welding parameters and joint configurations. Additionally, their programming capabilities allow you to modify welding paths and parameters quickly, accommodating project changes and customization requirements. This versatility ensures that you can meet the diverse needs of your clients and adapt to emerging industry trends seamlessly.

6. Future-Proofing Your Business

The manufacturing landscape is continually evolving, and businesses must adapt to stay ahead. By investing in a robotic welding system, you future-proof your operations by embracing automation and advanced technologies. This positions your business as a leader in the industry, ready to meet the demands of tomorrow. Whether it's increasing productivity, improving efficiency, or maintaining a competitive edge, a robotic welding system equips you with the tools to thrive in a rapidly changing world.

Conclusion

As metal fabricators, utilizing a robotic welding system from Cresco Custom Metals can catapult your business to new heights. The advantages of increased efficiency, superior quality, enhanced safety, cost reduction, versatility, and future-proofing make these systems an invaluable asset to any metal fabrication operation. Stay ahead of the competition and unlock the true potential of your business with our state-of-the-art robotic welding solutions.