Transforming Street Sweeper Cleaning Equipment with Advanced 3D Printing Solutions

In the rapidly evolving landscape of urban sanitation and maintenance, technological innovation plays a pivotal role in enhancing the efficiency, durability, and customization of equipment used for street cleaning. Among these advancements, 3D printing has emerged as a game-changer, enabling companies like ceksansweepers.com to develop state-of-the-art street sweeper cleaning equipment that meets the modern demands of cities worldwide.

Understanding the Role of 3D Printing in Modern Street Sweeper Technology

3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from digital designs. This innovative process has revolutionized multiple industries, and its application in manufacturing street sweeper cleaning equipment offers numerous advantages, including rapid prototyping, cost reduction, and the production of highly customized parts.

At Ceksan Sweepers, integrating 3D printing in the development of street sweeper cleaning equipment allows for:

- Faster development cycles - speeding up the time from concept to prototype.

- Enhanced customization - tailoring equipment to specific client needs or specialized cleaning scenarios.

- Cost-effective manufacturing - reducing material waste and labor costs.

- Rapid iteration - making quick modifications to designs without the need for expensive tooling.

- Complex geometries - producing intricate parts that would be challenging with traditional manufacturing.

The Benefits of Using 3D Printing in *Street Sweeper Cleaning Equipment*

Applying 3D printing technology to street sweeper cleaning equipment yields significant benefits, advancing overall operational efficiency and longevity. These advantages include:

1. Improved Durability and Material Optimization

Modern 3D printing materials, such as high-strength thermoplastics and composites, can withstand harsh environmental conditions, exposure to debris, and mechanical stress. This results in long-lasting parts that maintain their integrity over extended periods, reducing the need for frequent replacements.

2. Accelerated Customization and Rapid Prototyping

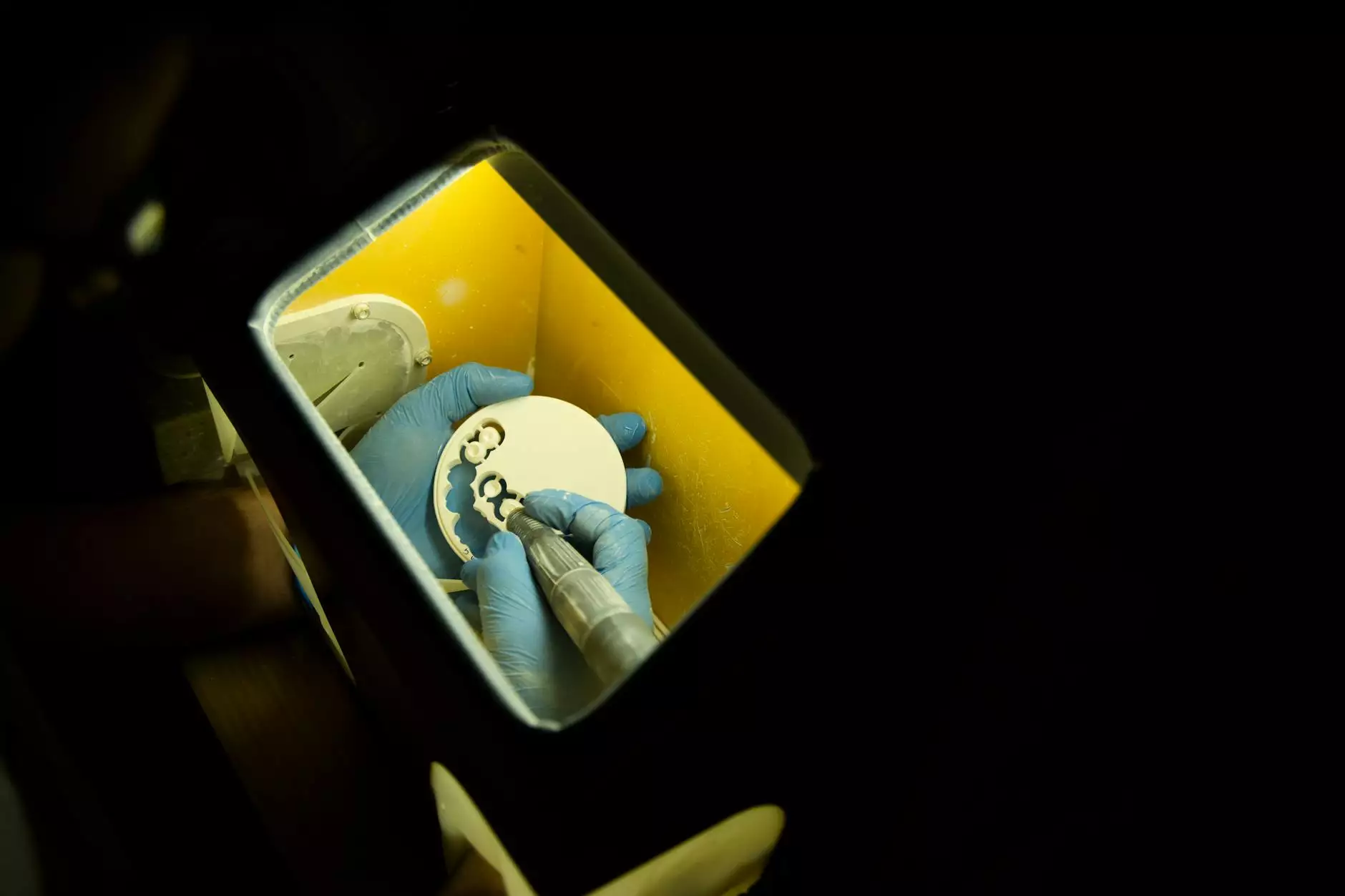

Every urban environment has unique cleaning challenges. With 3D printing, manufacturers can quickly produce customized parts—such as brushes, nozzles, or cleaning arms—that precisely fit a client’s specific requirements. This agility allows for rapid testing, modification, and deployment, ensuring optimal performance.

3. Cost Savings and Reduced Waste

Compared to traditional manufacturing, additive manufacturing minimizes material waste and reduces tooling costs. This cost efficiency enables companies to offer more competitive pricing and invest savings into research and development of innovative cleaning solutions.

4. Complex Geometries for Enhanced Cleaning Performance

3D printing offers the ability to create complex geometries that improve the efficiency of street sweeper cleaning equipment. For example, specially designed nozzles with optimized flow paths or intricate brush designs can be produced that effectively reach difficult areas and improve debris removal.

How Ceksan Sweepers Utilizes 3D Printing in Its Business Model

As an industry leader, ceksansweepers.com integrates 3D printing into its core development process to create cutting-edge street sweeper cleaning equipment. Their approach involves:

- Collaborative design sessions with clients to understand specific challenges and tailor solutions.

- Prototyping of parts and components using high-resolution 3D printers for rapid testing.

- Iterative improvements based on real-world feedback, facilitated by quick modifications enabled by 3D printing.

- On-demand manufacturing of spare parts and accessories, reducing downtime and maintenance costs.

The Future of 3D Printing in the Street Sweeper Industry

The future of street sweeper cleaning equipment is intertwined with continued advancements in 3D printing. Emerging technologies such as multi-material printing, large-scale additive manufacturing, and the integration of smart materials promise even more innovative solutions. Key trends include:

- Use of sustainable and biodegradable materials for environmentally friendly equipment parts.

- Enhanced durability through the development of specialized composite materials.

- Integration of sensors and IoT technology within 3D-printed components to enable real-time monitoring and predictive maintenance.

- Mass customization for municipal and commercial clients with unique cleaning needs.

Case Studies: Successful Implementations of 3D Printing in Street Sweeper Equipment

Numerous municipal sanitation departments and private contractors have experienced the benefits of 3D printing by adopting customized, durable parts designed specifically for their needs. For example:

Municipal Street Maintenance in Major Cities

Cities seeking to upgrade their street cleaning fleet have partnered with manufacturers like Ceksan Sweeper to develop tailored nozzles and brushes that提升 debris collection efficiency, particularly in congested urban environments.

Private Waste Management Companies

Private firms deploying street sweeper cleaning equipment equipped with 3D printed components report reduced downtime due to on-site manufacturing of spare parts, ensuring continuous operation with minimal interruption.

Choosing the Right 3D Printing Technologies for Your Street Sweeper Needs

Different 3D printing techniques offer various benefits. When selecting the appropriate technology for street sweeper cleaning equipment, consider factors such as material properties, precision, and scale. Key methods include:

- Stereolithography (SLA): Ideal for high-resolution, intricate parts requiring fine detail.

- Fused Deposition Modeling (FDM): Cost-effective for larger, less detailed components such as mounting brackets.

- : Suitable for durable, functional parts with complex geometries.

- Multi-material printing: For producing multi-functional parts with different material properties in a single build.

Conclusion: Embracing Innovation for a Cleaner Future

As cities grow and environmental standards become increasingly stringent, the need for efficient, customizable, and sustainable street cleaning solutions will only intensify. 3D printing stands at the forefront of this revolution, offering unparalleled opportunities to innovate, optimize, and adapt street sweeper cleaning equipment to meet these challenges. Companies like ceksansweepers.com are leading the way by leveraging additive manufacturing to create next-generation cleaning solutions that are not only more effective but also more cost-efficient and environmentally responsible.

Investing in 3D printing technology is investing in the future of urban sanitation—one where smarter, more durable, and highly customized street sweeper cleaning equipment ensures cleaner streets and healthier communities around the globe.